By Wade Abel, CG, Director of Gemological Services, AGS Laboratories

Diamond cut is a direct reflection of the craftsmanship of the artisan who put the diamond on the wheel. The design of the cut, the execution of that design by the cutter, and the high polish possible with a diamond are all factors that contribute to the finish of the diamond.

When diamond graders assess diamonds for polish and symmetry, the visibility, as well as the number of faults, are taken into consideration.

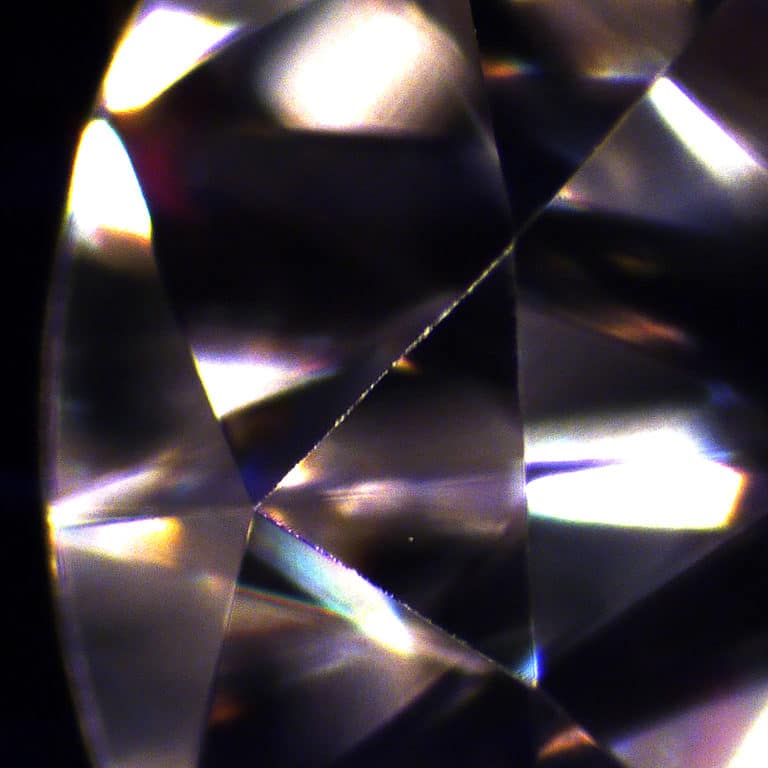

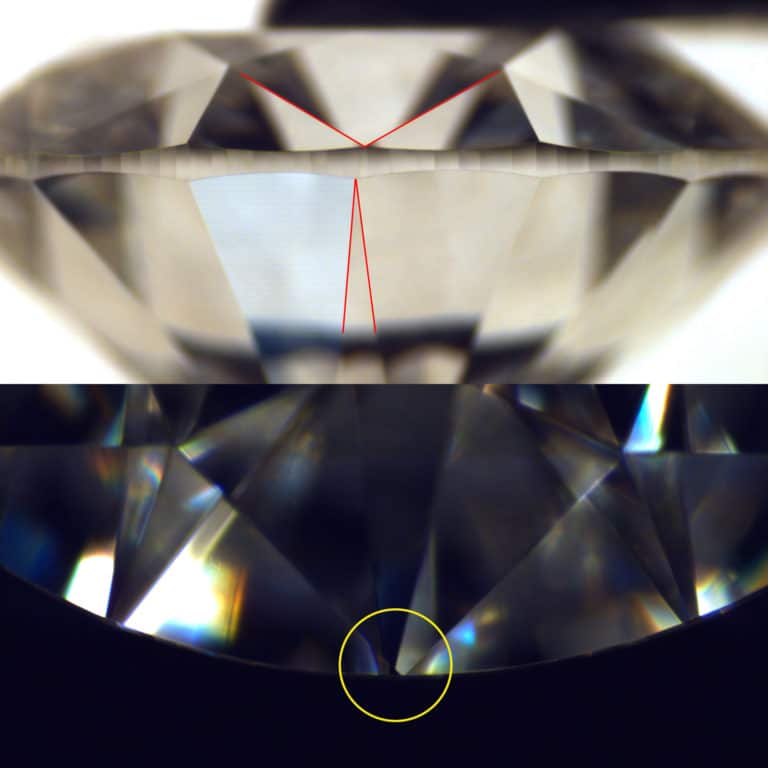

As with diamond clarity, polish and symmetry are assessed and assigned grades at 10x magnification under a standardized lighting environment. If a polish or symmetry fault is not seen in those conditions, there is no grade deduction. (Figure 1)

Diamond Polish

Diamond polish is the smoothness of the facet surfaces and the condition of the facet edges.

Gem quality diamonds have the ability to attain a very high luster, which has the potential to provide a very smooth and reflective surface with extremely well-defined facet edges or junctions. (Figure 2)

Here are some of the most common polish faults seen in diamonds.

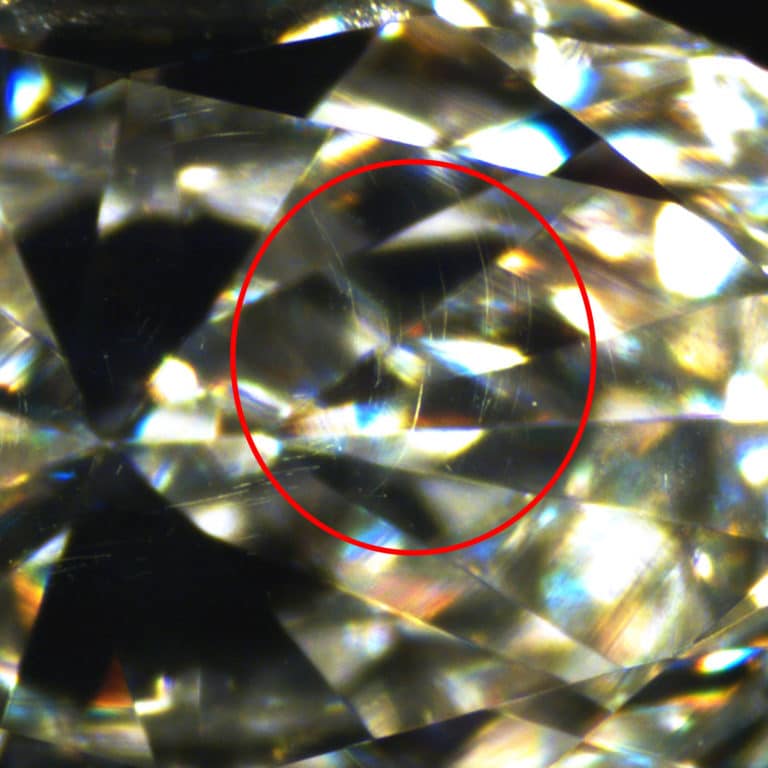

Abrasion

Abrasion is a series of small nicks or pits along a facet junction. These are usually in a continuous line and appear white and frosty. Abrasion can be caused as a result of the cutting process or from improper handling of the diamond. (Figure 3)

Polish Lines

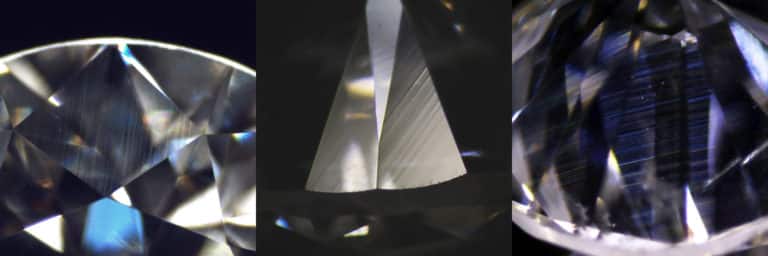

Polish lines are areas where there are multiple fine parallel lines that continue in one direction on the same facet. These may be seen in different directions on other facets.

This may be a result of the polishing wheel or because of the hardness of the diamond material in the direction of the polish. Polish lines can appear whitish, transparent, or rainbow (caused by the diffraction of light passing through them). (Figure 4)

Scratch

Scratches differ from polish lines as they do not appear as multiple, parallel lines facing the same direction. They can appear on any facet and can be curved or straight. They appear white and lack depth, which differentiates them from a feather. Scratches can be caused by the polishing process or by improper handling of the finished diamond. (Figure 5)

Diamond Symmetry

Diamond Symmetry is the cut design’s execution, which includes the outline and geometric balance with the correct placement and shape of each facet, including the points where the facets meet.

Symmetry plays a large role in the evenness of the brilliance and contrast patterns as well as the appearance and beauty in general. There are aspects of the faceted diamond’s symmetry that are considered major factors and others that are not. The major factors are faults that may be noticed without magnification, while the others normally require some magnification to notice and identify.

Major Symmetry Faults

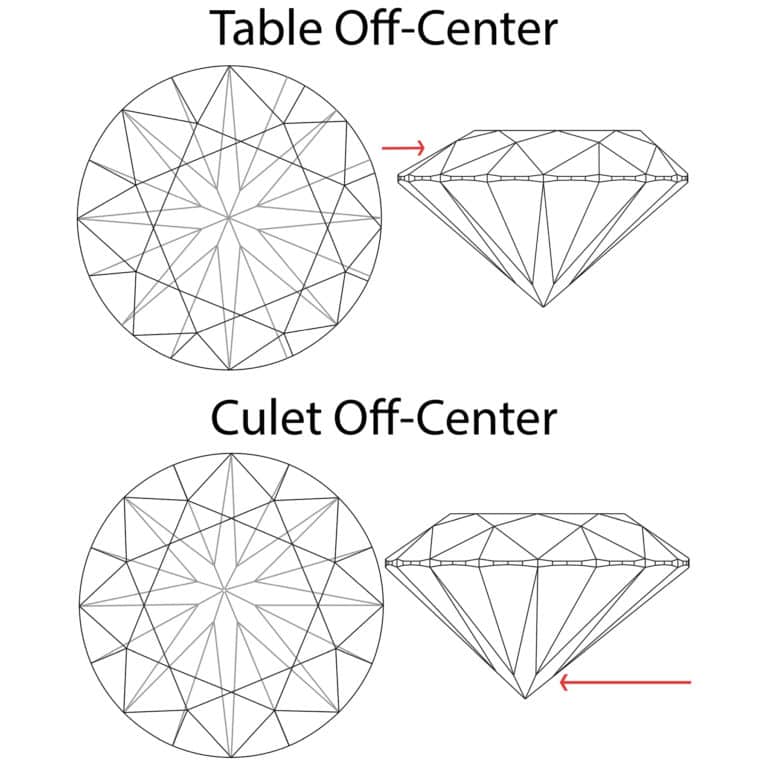

Major symmetry faults include the outline of the diamond or if the table or culet is not centered. Often, if major symmetry faults exist, there are other symmetry issues as well. The outline of the diamond is perhaps the most obvious. If a round brilliant diamond is out of round, the outline will look uneven, potentially with noticeable bulges or flat areas. (Figure 6)

When the table facet or the culet are not centered, the diamond can look off-center overall, depending on the severity. When one diamond is off-center, it can make the other diamonds look off and will impact the overall appearance. (Figure 7)

Most other symmetry faults require magnification to identify and notice. These faults usually do not have as great an impact as the major faults on the grade of a diamond unless they are plentiful or obvious. Here are some of the most common symmetry faults encountered when grading diamonds.

Alignment

When the facets on the crown of the diamond do not line up with the facets on the pavilion, this is known as an alignment fault. Areas near the outer edge of the diamond do not line up and can look crooked or out of place. (Figure 8)

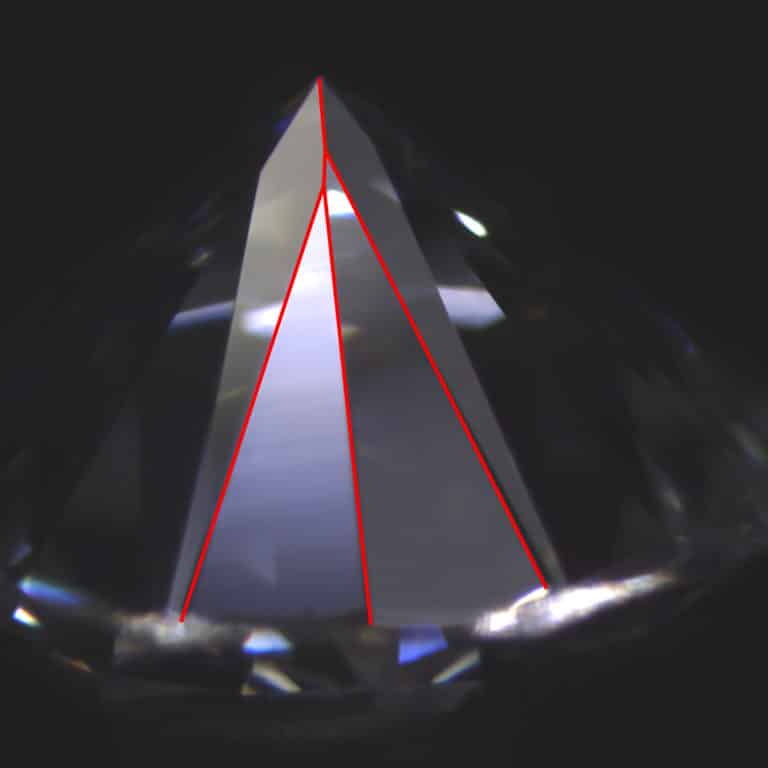

Pointing

Where the facets come together and meet, all facet junction lines should come together at a single point. If this is not the case, there is a pointing fault. This can have more impact the closer it is to the center of the diamond. If pointing exists, there are most likely other symmetry faults like misshapen facets. (Figure 9)

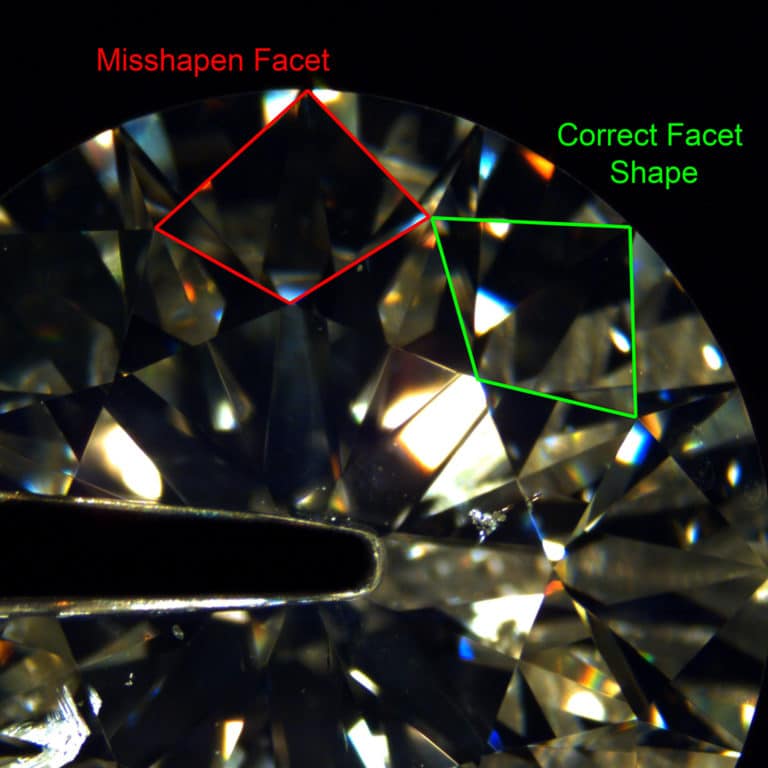

Misshapen Facets

Misshapen facets are facets that are not the same shape as other facets of the same type. Sometimes there can be an extra edge to the facet, or the facet does not have the exact symmetry. It could look a bit squished or uneven. (Figure 10)

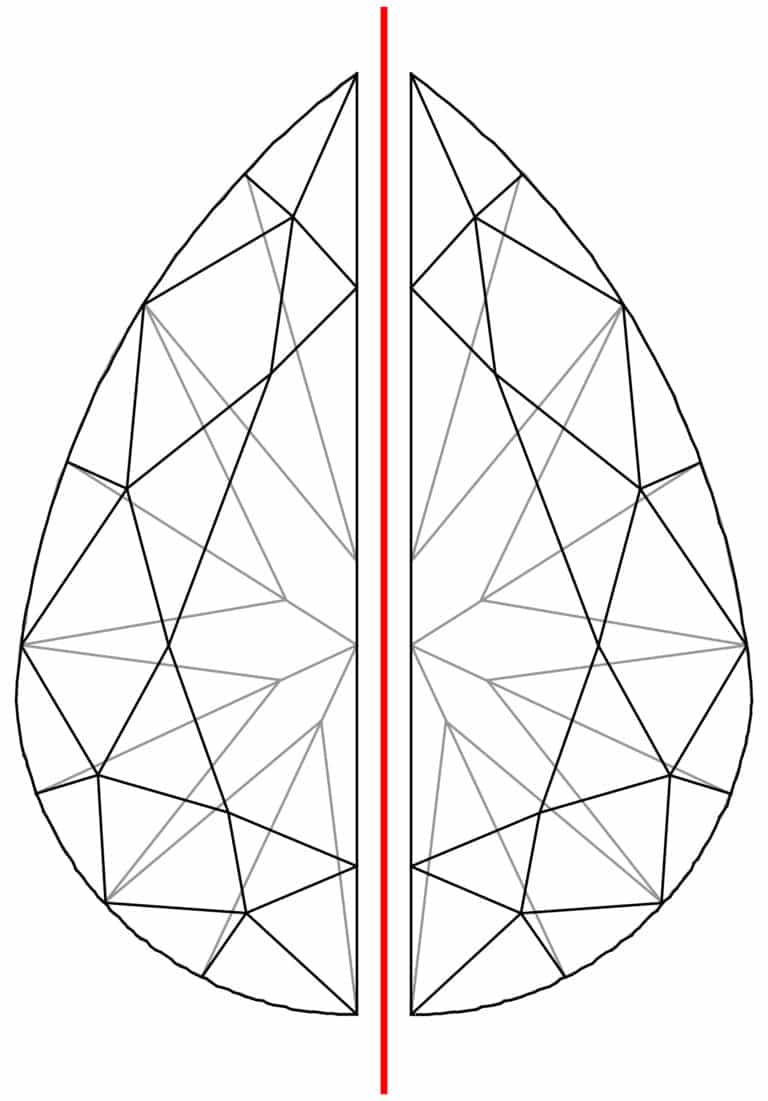

Symmetry of Fancy Shapes

When considering the symmetry of fancy shape diamonds, fold symmetry is used. Take a pear shape for instance. There is a point at one end and a rounded contour on the other. (Figure 11) For these, fold symmetry allows the diamond grader to compare opposite and corresponding facets. The facets, facet junctions, and meet points on one side must be the same as those on the other side of the “fold.” This technique is used for most fancy shapes.

Although many of these features seem small, together they can greatly impact the appearance of a diamond. When cutting gemstones, the goal is to create a beautiful sculpture that sparkles and captures the imagination. Avoiding polish and symmetry faults help accomplish that goal.