By John Carter, CGA

If you’ve seen any of the Making the Grade videos on ags.org, you know I’m a raving advocate of the AGS Laboratories Light Performance grading system. As Chair of the AGS Laboratories Advisory Committee, I have the pleasure of working with the incredible team at our Lab. I’m constantly impressed with the intelligent, passionate professionals and gemologists who work behind the scenes on our grading.

For this issue, I wanted you to hear from one of these team members directly on what makes the Light Performance system so different, which is why I interviewed Wade Abel, CG, Director of Gemological Services. Wade is front and center of the Lab’s daily grading activities and is the perfect person to discuss what sets the Light Performance grading system apart from other systems.

Chair: AGS Laboratories Advisory Committee

In case anyone doesn’t know, please give us a brief history of the AGS Laboratories Light Performance Grading system.

The AGS Diamond Grading Standards were created in the mid-1960s. At that time, the cut grade was based on the analysis of the diamond’s major symmetry and proportion as well as the symmetry and polish details, calculating the deductions based on this analysis. Measurements were by hand and the symmetry and polish details were determined by the AGS member.

After the Lab opened in 1996, the desire for a cut grade for fancy shapes was incentive to begin cut grade research. A research team was assembled, and in 2001, the cut grade research began. This team consisted of optical physicists, mathematicians, and gemologists led by Peter Yantzer, ECG.

Technology was available that facilitated researching new ways of assessing cut. In 2005, a system was introduced to the industry that provided a new way to analyze the cut of diamonds for the round brilliant and princess shapes, then, emerald and oval shapes. This system uses scientifically proven methods that analyze and provide descriptions of the way a diamond returns light to the eye—how light performs, thus Light Performance!

What makes the AGS Light Performance grading system different?

Other grading systems, and the original AGS standard, are mainly based on a diamond’s proportions. The averages of the proportions are used and applied to lookup tables that provide a grade. What makes the AGS Light Performance grading system different is that it simulates how light interacts within the diamond.

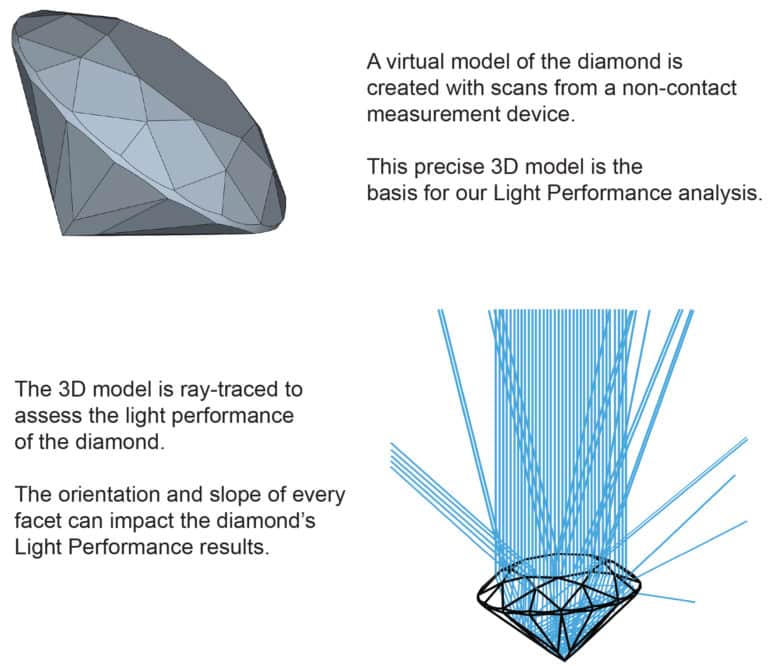

One of the most important components of the Light Performance system is a 3D virtual model of the diamond. This is created with high-precision measurement scans using a non-contact measurement device. We use ray-tracing technology that provides information about how thousands of rays of light would interact within the diamond. This takes into account each individual facet using the 3D virtual model, not just the average proportions. The output from the proprietary ray-tracer is an analysis of Brightness, Contrast, Dispersion, and Leakage represented by very precise numbers. These numbers combine to provide the Light Performance grade.

How has the system changed the way diamonds are cut?

I would like to think it has created a standard for diamond cutters to aspire to. The system itself raised the bar for standard rounds and, for the first time, created a standard for fancy-shape diamonds. The relative precision of the diamond’s facets deliberately placed with the correct angles can be very difficult. Because one factor directly impacts other factors, an ideal (pun intended) combination must be accomplished. Although extremely difficult, we are seeing diamonds come through the Lab that are AGS Ideal® every day. Marketing campaigns and brands have been created around the AGS Ideal® cut grade.

Additionally, this system provides our awesome research analysts, led by Jason Quick, RJ, and Brock Wilke, RJ, with data that can be used to provide insight and feedback to clients on how diamonds can be cut to this standard. By providing guidance to diamond cutters and clients, the number of AGS Ideal® diamonds is increased in the market.

Also, technologies have been developed that assist diamond cutters to achieve a high level of cutting precision. These developments have potentially changed the industry and allowed for new cutting innovations.

Describe what goes into the AGS Cut Grading System?

The AGS Cut Grading System is more than just Light Performance. Of the 11 factors that make up the full Cut Grade, Light Performance provides four: Brightness, Contrast, Dispersion, and Leakage. The other factors are related to the proportions and finish (polish and symmetry) of the diamond. This ensures that what is reported is a comprehensive analysis of how the diamond’s cut will impact the appearance of the diamond.

What advice do you have for anyone who wants to sell their diamonds with your report? How can they more easily discuss it with their customers?

The AGS Cut Grade scale is divided into 11 grades which provides a precise description of what your customer will see and experience when looking at and admiring their diamond. This can make communication of the grade easier in comparison to others.

For the retailer or supplier that wants to sell diamonds with AGS Laboratories reports, I would point out the Light Performance grade on reports where it is present. This can be used to start a conversation with your customers to talk about the detail and precision of craftsmanship that goes into creating a diamond with a high AGS Cut Grade. All that you need is a little knowledge of how the Light Performance grade is determined.

Explaining the research and technology behind the Light Performance grade may not be appropriate for all customers, however, there will be some that will love the story of how each individual facet has been analyzed to provide something so special. AGS is the only lab to combine decades of diamond cutting knowledge with new technologies to provide a one-of-a-kind Light Performance system that supports the craftmanship of highly-skilled diamond cutters.

An easy way to say it is, “All aspects of the craftsmanship of diamond cut are taken into consideration with the AGS Cut Grade, down to each individual facet. One of the most important aspects of a diamond is the sparkle and light you see when looking at it. Each facet plays a part to create that. The analysis of each of those facets with AGS Light Performance provides the assurance, scientifically-backed by years of research and technology, that the grade describes the beauty.”